Why are PCBs usually green?

Have you ever wondered why green PCBs are so common? There are several proper answers and we are more than happy to share them with you.

First of all, the actual 'bare' PCB is covered by a solder mask, which makes the PCB a certain color. The color you see is only what is placed on the PCB.

So why is green the most frequently selected color? Firstly, it is the color which is the least tiring to the eye. This may have been more important in the past - currently most quality control processes are automated. Nowadays, despite automation in general, there are still situations where naked eye inspection is needed.

Epoxy glass, originally used to make solder masks, is actually green. Therefore, green pigments were traditionally used, and research and development to improve solder mask also took place within this color. This is also the reason why solder mask is still preferred in some criteria.

There is another reason mentioned in some sources - although unconfirmed, it is definitely interesting. Because of its greatest durability, it was the green solder mask that was ordered by the US military. For this reason, PCB suppliers had the largest stock of masks in this color, which also meant the most availability for the civilian customers.

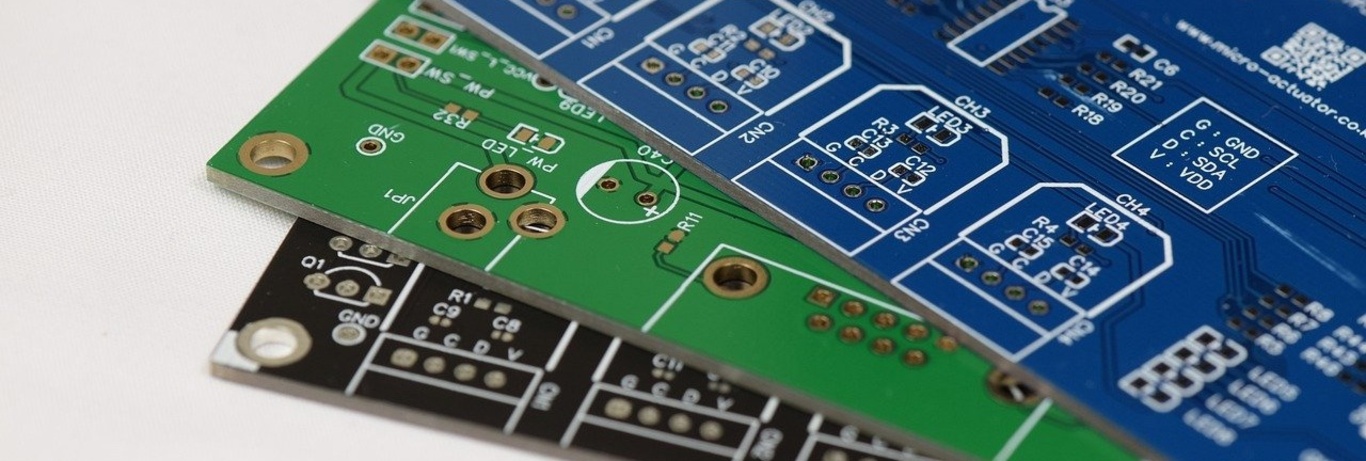

Although there are now masks in a whole range of colors on the market, green solder masks are still the most popular.