The 8D method as one of the ways to solve problems in EMS

There are many different methods used in EMS to improve processes and deal with potential problems. One of them is 8D - and you will find out about it in the article below.

One of the most important goals of our Quality Department is to prevent mistakes that have not yet occurred. How to do it? The best way is to draw the right conclusions from situations that have already happened before in various parts of the process. Various tools and methods help us in this, and 8D is one of them. We would like to focus this article on it.

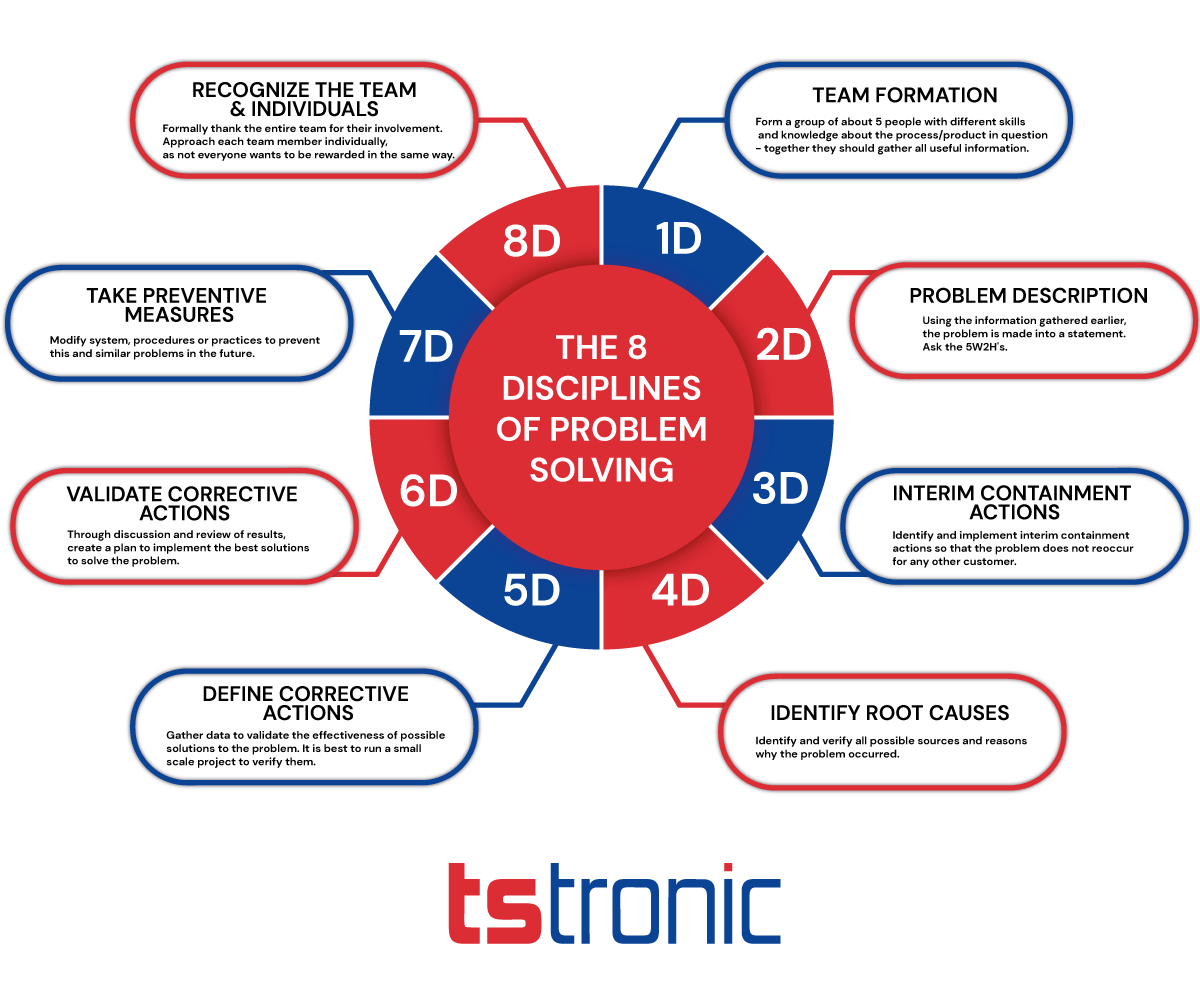

So what is 8D? As the name suggests, it is a set of 8 points of analysis, which, when carefully filled in and analyzed, will lead to a solution of the problem. The 8D report encourages us to implement changes and minimizes the chance of errors occurring again. In this way, the company constantly improves and the possibility of potential problems decreases.

What consists of the 8D Report? The graphic below illustrates it perfectly: